What is the difference between an etched stainless steel and aluminum plaque?

Etched Stainless Steel plaque with Polished "Mirror" finish & Medium Grey Infill

Etched Stainless Steel plaque with Polished "Mirror" finish & Medium Grey Infill

One common question we are asked by our clients is the difference between two visually similar metals: stainless steel and aluminum. Both are silver in color, yet they are quite different when it comes to their other characteristics, specifically regarding their density and weight.

etched stainless steel

Dense and Durable | Corrosion resistant | Non-porous surface

Stainless Steel is an excellent choice for a plaque exposed to a significant amount of wear and tear and varying weather conditions. The benefit of stainless steel is its exceptional durability and its corrosive-resistant surface. Stainless steel is less likely to dent or warp over time. It is also resistant to discoloration, because of its non-porous surface.

CAST ALUMINUM

Softer metal | Light weight | Cost-effective

Cast aluminum plaques have unique benefits of their own. Although aluminum is a much softer metal, it is significantly lighter in weight than stainless steel. It is a great choice for interior plaques and can be mounted to just about any type of wall, stone or platform, as can stainless steel. At our studio, aluminum is a great alternative to stainless if you are looking to create a large custom plaque on a small budget. Aluminum is not recommended for plaques that are inset into the ground or susceptible to a significant amount of wear and tear. Aluminum is a soft metal and can bend and warp if it is dropped or damaged.

metal finishes

Both metals are silver in color, which can give plaques a contemporary look—a pleasant alternative to the traditional cast bronze plaque. Both aluminum and stainless steel plaques can be finished in three different fashions: Random Orbital, Satin and Polished finishes.

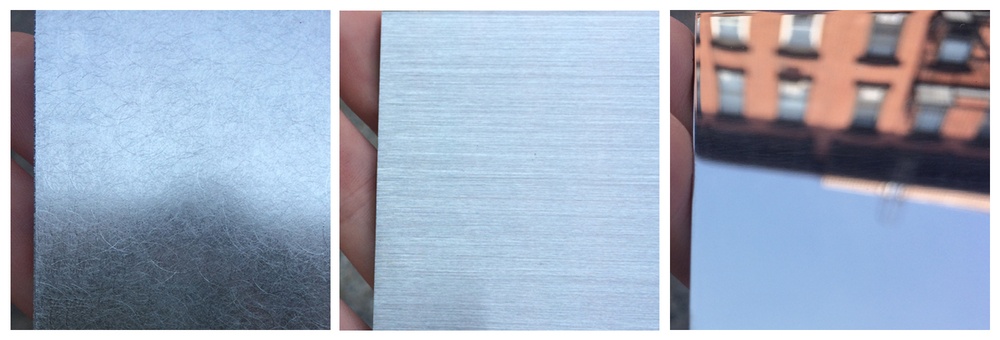

On Stainless Steel (from left to right): Random Orbital, Satin and Polished finish

On Stainless Steel (from left to right): Random Orbital, Satin and Polished finish

The random orbital finish is a great choice for a plaque that is installed in an area susceptible to scratching, bumping, etc. Random orbital subtly disguises these scratches, as the sander used in our studio to produce this finish creates hundreds of small textural strokes on the surface of the plaque in every direction. The finish gives the plaque a buffed look and creates a disguise for any accidental scratch or dent, which could otherwise ruin the look of a perfectly smooth plaque. Alternatively, the satin, or “brushed”, finish can be added to the plaque, which is created by a different type of sander in our studio. This is our most popular finish choice. A satin finish is created by adding a horizontal stroke to the plaque, giving it a smooth brushed surface. It is more susceptible to scratches, but mounted in the right place, it has a very crisp and refined look. The final option is a polished finish, which is exceptionally unique. The metal surface is polished until it is reflective, which is why it is also referred to as a mirror finish. This is a great finish if you want to draw attention to the plaque from a distance. It is often used on lobby plaques and general signage, in both interior and exterior settings.

For more questions on the difference between these metals and their finishes, check out our plaque options or reach out to us at masterworkplaques@gmail.com.